/

5HP KB Electronics KBDA-48 NEMA4X Digital Epoxy White VFD 380/460VAC 3PH INPUT 9662

5HP KB Electronics KBDA-48 NEMA4X Digital Epoxy White VFD 380/460VAC 3PH INPUT 9662

Part Number:

KB9662Model/Spec Number:

KBDA-48 WHITEManufacturer:

KB ElectronicsManufacturer Part Number:

9662Shipping Details

Weight:

13 lbsDimensions:

14 x 12 x 11 inchesHS Code:

8504.40.4000UPC:

024822096621Technical Details

Specifications

Series: | KBDA |

Output HP: | 5 |

Output KW: | 3.7 |

Input Voltage: | 460//380 |

Input Phase: | 3 |

Hz Rating: | 60//50 |

Output Voltage: | 460//380 |

Output Phase: | 3 |

Output Amperage: | 8.3 |

Line Reactor: | None |

Documentation

Additional Information

KBDA-48 Digital AC Drive with White FDA approved finish.

KBDA-29D Adjustable Frequency Drives are variable speed controls housed in a rugged NEMA-4X / IP-65 washdown and watertight die-cast aluminum enclosure. This drive is designed to operate 440-480 Volt 50 & 60 Hz 3-phase AC induction motors from subfractional thru 2 HP. The sine wave coded Pulse Width Modulated (PWM) output provides high motor efficiency and low noise. Adjustable Linear Acceleration and Deceleration make the drive suitable for soft-start applications.

The KBDA is easy to install and operate.

Multi-Function Keypad – The keys are used to operate the drive, change operating parameters, reprogram functions, and change the display output (Run/Stop, Forward/Reverse, Up, Down, Shift/Reset, Jog-Local/Remote, Program/Display, Read/Enter).

4-Digit LED Display – Provides readout of drive operating parameters and programming functions. Displays Output Frequency, Motor RPM, Output Current, Output Voltage, Bus Voltage, Function No. Codes and Values, Fault Codes, and Custom Units.

Setting the drive to specific applications is accomplished using the Multi-Function Keypad, which provides easy operation and programming of the drive. To facilitate programming, all similar functions are presented in common groups. For more advanced programming, PC based Drive-Link™ software is available.

The 4-Digit LED Display provides readout of drive operating parameters and programming functions and displays Output Frequency, Motor RPM, Output Current, Output Voltage, Bus Voltage, Function Codes and Values, Fault Codes, and Custom Units. In addition to operating the drive, the Multi- Function Keypad is used to change drive operating parameters, reprogram functions, and change the display output. The LEDs provide indication of the drive’s status and operating mode (Hz, PGM, LCL/REM, STOP, FWD, REV, OL, JOG/REM).

Main Features – Adjustable RMS Current Limit and I2t Motor Overload Protection.* Flux Vector Compensation with Static Auto-Tune and Boost provides high torque and excellent load regulation over a wide speed range. Power Start™ delivers over 200% motor torque to ensure startup of high frictional loads. Programmable Injection Braking provides rapid motor stop. Electronic Inrush Current Limit (EICL™) eliminates harmful AC line inrush current, which allows the drive to be line switched. A Multi- Function Output Relay is provided, which can be used to turn on or off equipment or to signal a warning if the drive is put into various modes of operation. Models KBDA-29**, 45, 48 also contain AC Line Phase Loss Detection. The drive is suitable for machine or variable torque (HVAC) applications.

Standard Front Panel Features – 4-Digit LED Display, Multi-Function Keypad, Status Indicator LEDs, and a Main Speed Potentiometer

Dimensions approx. 9.80" X 7.55" X 7.25".

Agency approvals: UL, CE, CSA, C-Tick.

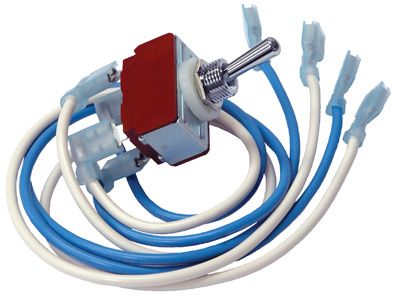

On/Off AC Line Switch – P/N: 9532, Disconnects the AC line. Mounts on the enclosure cover and is supplied with a switch seal to maintain liquidtight integrity.

IODA Input/Output Multi-Function Board – P/N: 9668 Provides a variety of functions, which include preset frequency, up/down frequency control, signal isolation, isolated output voltage for controlling auxiliary devices, open collector outputs, and output relay contacts. See Appendix A, on pages 42 – 54 in the user manual provided in "FILES". See Function Groups 7 – 9, on pages 36 – 38.

AC Line Filter (1) – P/N: 9479, Provides Class A RFI (EMI) suppression.

DIAC Modbus Communication Module – P/N: 9517 Allows direct communication between drive and Modbus(2) protocol.

Liquidtight Fittings - P/N: 9526, Provides a liquid-tight seal for wiring the drive. Kit includes necessary liquid-tight fittings

Notes: 1. Complies with CE Council Directive 89/336/EEC Industrial Standard. 2. Other protocols available – contact our Sales Department.

Related Products

Shipping Details

Weight:

13 lbsDimensions:

14 x 12 x 11 inchesHS Code:

8504.40.4000UPC:

024822096621